In a word, powder coating is the process of painting or coating surfaces or items. In contrast to conventional liquid paints, this method involves applying a powder to a particular area or surface; thus, it is also known as the dry paint method. The powder consists of minute, dried resin particles that have been precisely grounded to bond with the electrically charged particles on the surface.

This method offers various benefits over alternative painting or coating techniques. The primary advantage is that the overspray may be recycled. It generates a product with no waste, which reduces expenses. In addition, powder coating emits fewer VOCs (Volatile Organic Compounds), which can be environmentally hazardous.

In addition, it does not produce hazardous waste and does not require the use of chemical compounds or solvents throughout the process. It provides a coating that is substantially thicker and more durable than any other method, allowing it to be durable and corrosion-resistant. Due to the excellent smoothness of the coating, there should be no tangible difference in appearance between horizontal and vertical coated surfaces.

Consequently, a number of businesses have switched from traditional wet paints to powder coatings. The majority of businesses that implemented this method for their finishing process realized that their material consumption had increased considerably. During the operation, there would almost definitely be no running or leaking of the mixture.

As a consequence, a strong coating will form. It is frequently less costly than other accessible painting techniques. Less equipment is required to operate a powder production line than for conventional wet paints. Due to its low cost, the majority of firms opt to employ it, especially for large-scale projects.

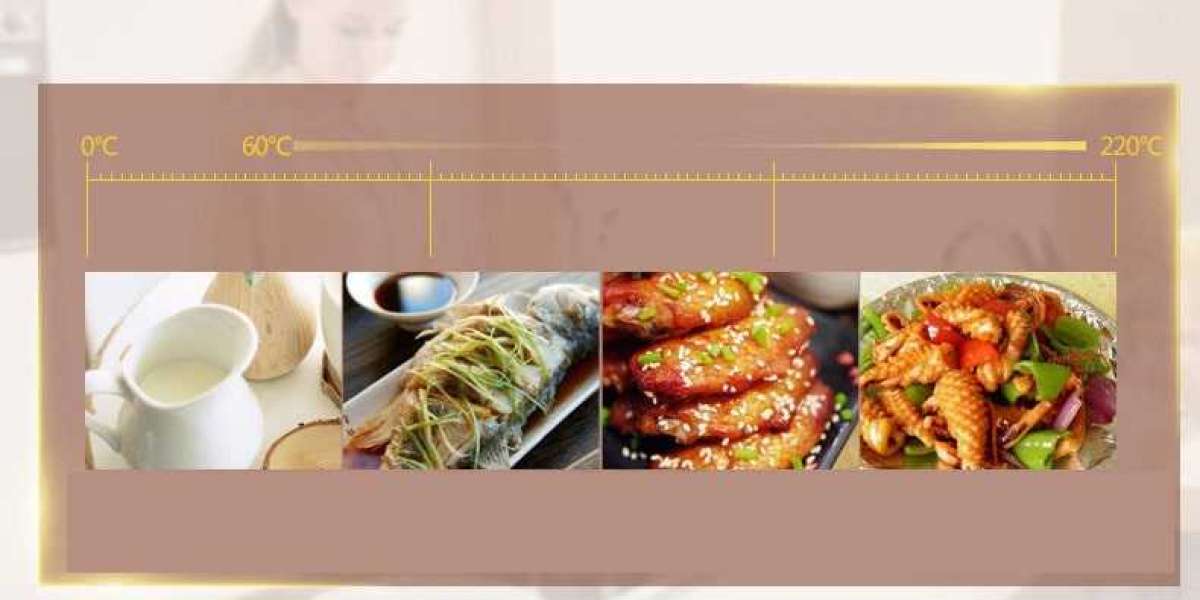

The powder coating process is not complicated; in fact, it is less complicated than the conventional method of coating surfaces. Preparation, application of powder, and curing are the three phases. Preparation requires the elimination of any dirt or grime from the object to be coated. Ensure that the surface is sufficiently clean to provide a very smooth finish.

Sandblasting NJ understands the importance of powder coating metal finishing for a wide range of sectors, including industrial manufacturing, metal fabrication, and automotive components. Machine shops often rely on Rustylions for superior finishing services. For powder coating services, call Rustylions Powder Coating at 1 347 613 8103 or 973 459-8515.